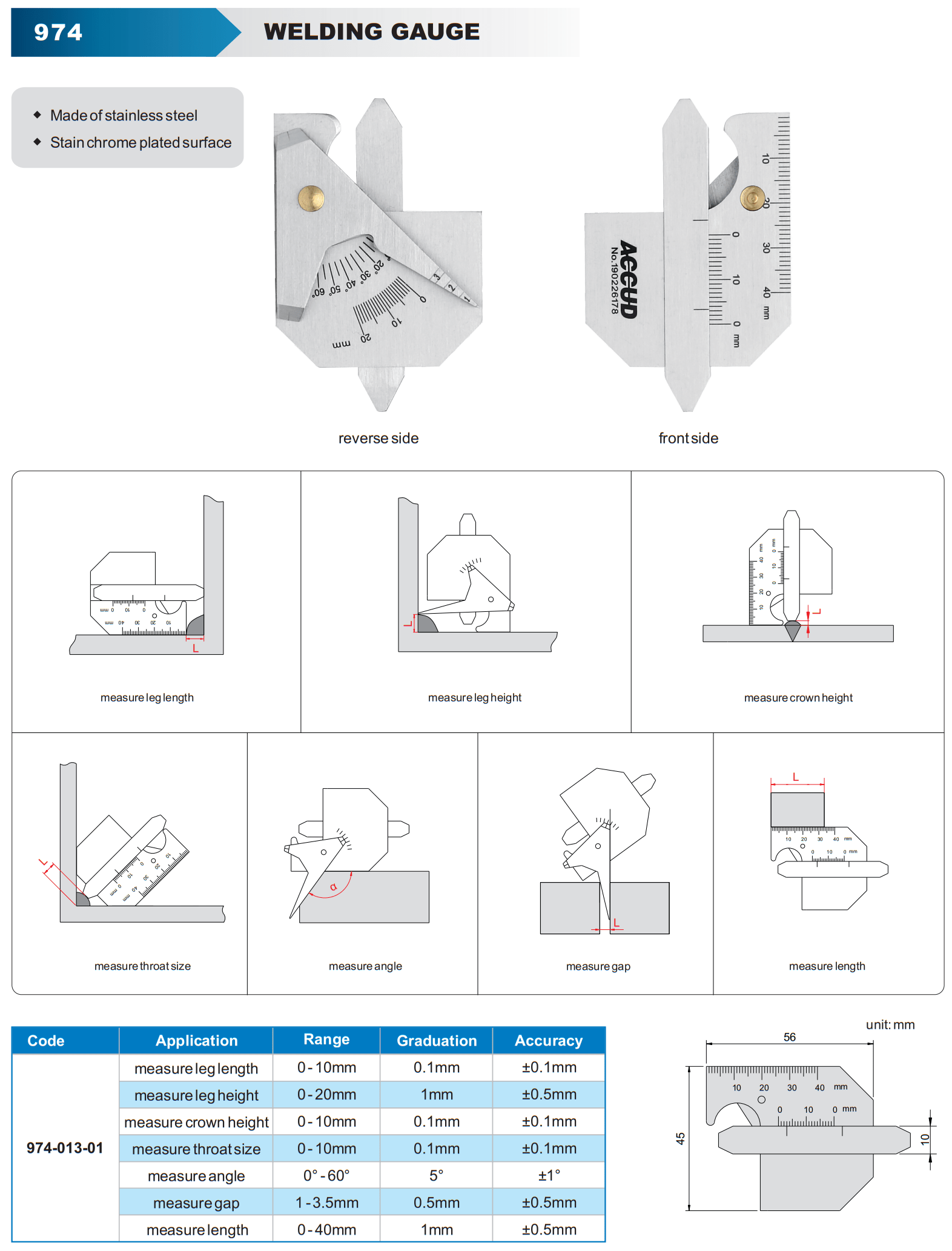

WELDING GAUGE 7 X MEASURING APPL. 10,20,1-35,40MM,60DEG RANGE S/STEEL

SERIES 974

A universal welding gauge is used to measure various parameters related to welding, such as bead width, depth, and undercut. By using a universal welding gauge, you can ensure that your welds meet the required standards and are of high quality.

- Measure leg length

- Measure leg height

- Measure crown height

- Measure throat size

- Measure angle

- Measure gap

- Measure length

Applications:

- Welding inspection: Assessing the quality of welds.

- Quality control: Ensuring compliance with welding standards.

- Research and development: Analyzing welding processes.

Key Features:

- Multiple measuring blades: Allows for measuring different parameters like bead width, depth, and undercut.

- Accuracy: Provides precise measurements for quality control.

- Durability: Built to withstand harsh industrial environments.

- Portability: Often has a compact design for easy carrying and use.

Technical Specifications

How to Use a Universal Welding Gauge:

-

Measure Leg Length: For fillet welds, place the gauge’s appropriate edge or cutout against the weld and check that the leg length meets the required specifications.

-

Check Throat Thickness: Use the gauge to measure the throat thickness by aligning it between the weld’s root and face.

-

Measure Weld Reinforcement: Place the gauge on the surface to check the weld reinforcement height, ensuring it’s within acceptable limits to prevent excess or insufficient material.

-

Check Angles: For V-groove or bevel welds, use the angle measurement feature to ensure the proper angle of the weld.

-

Undercut Depth Measurement: Position the gauge along the weld toe to measure any undercuts and verify that the depth is within allowable limits.

-

Measure Gaps (Fit-Up): Before welding, use the gauge to measure the gap between parts to ensure proper alignment and fit-up for strong joints.