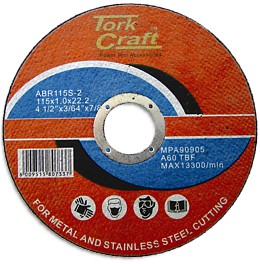

CUTTING DISC STEEL & SS 115 X 1.0 X 22.2 MM 10 PACK

- 10 Pack

Disc: Ø115mm

Thickness: 1mm (±0.2mm)

Arbor: Ø22.2mm

Compatible with 115mm dia. angle grinders.

Manufactured from high quality Resin

and Corundum. Designed for steel cutting only.

Application:

- Steel cutting

- Metal cutting

- Steel Profile cutting

- Sheet steel cutting

- Manufacturing

- Construction

A steel grinding disc is used for:

- Mild steel cutting

- Car body panel work

- Stainless steel cutting

- Metal cutting

Features

- Quick cutting blade.

- Increased durability and disc life.

- Industrial graded.

| Description | Specification |

| Packaging Type | Bulk |

| Package Weight | 280g |

| Disc | Ø115mm |

| Thickness | 1mm (±0.2mm) |

| Arbor | Ø22.2mm |

| Max RPM | 13 300 |

| Safety Standard | EN12413 |

| Construction | A60 TBF |

| MPA Z-03789 |

What is a grinding wheel?

A grinding wheel is a tool used to grind down, polish or cut material such as metal or glass. Like sanders, it uses abrasive grains to wear away the surface in minute particles. Grinding actually sharpens the wheel by breaking those grains and creating new sharp points.

What is a grinding wheel made of?

A grinding wheel is made from several chemical and mineral ingredients. The formula varies according to what the wheel will be intended to grind, polish or cut.

For metalwork, they use abrasives that are aluminium oxide based. For cutting cement, stone and other non-metal objects they use abrasives that are silicon carbide based.

Even within those two categories, the formula differs between say, a wheel designed for hard steel versus one designed for soft steel. Computer programmed scales automatically weigh the various ingredients, including additives such as iron oxide (for wheels that cut or grind iron) and the mineral Cryolite (which lubricates the abrasives). Powdered and liquid resins bond all these ingedients together.

The grinding disc is then reinforced with fibre glass and a galvanised steel ring goes into the centre of each wheel. The steel ring protects the shaft that spins the grinding wheel.