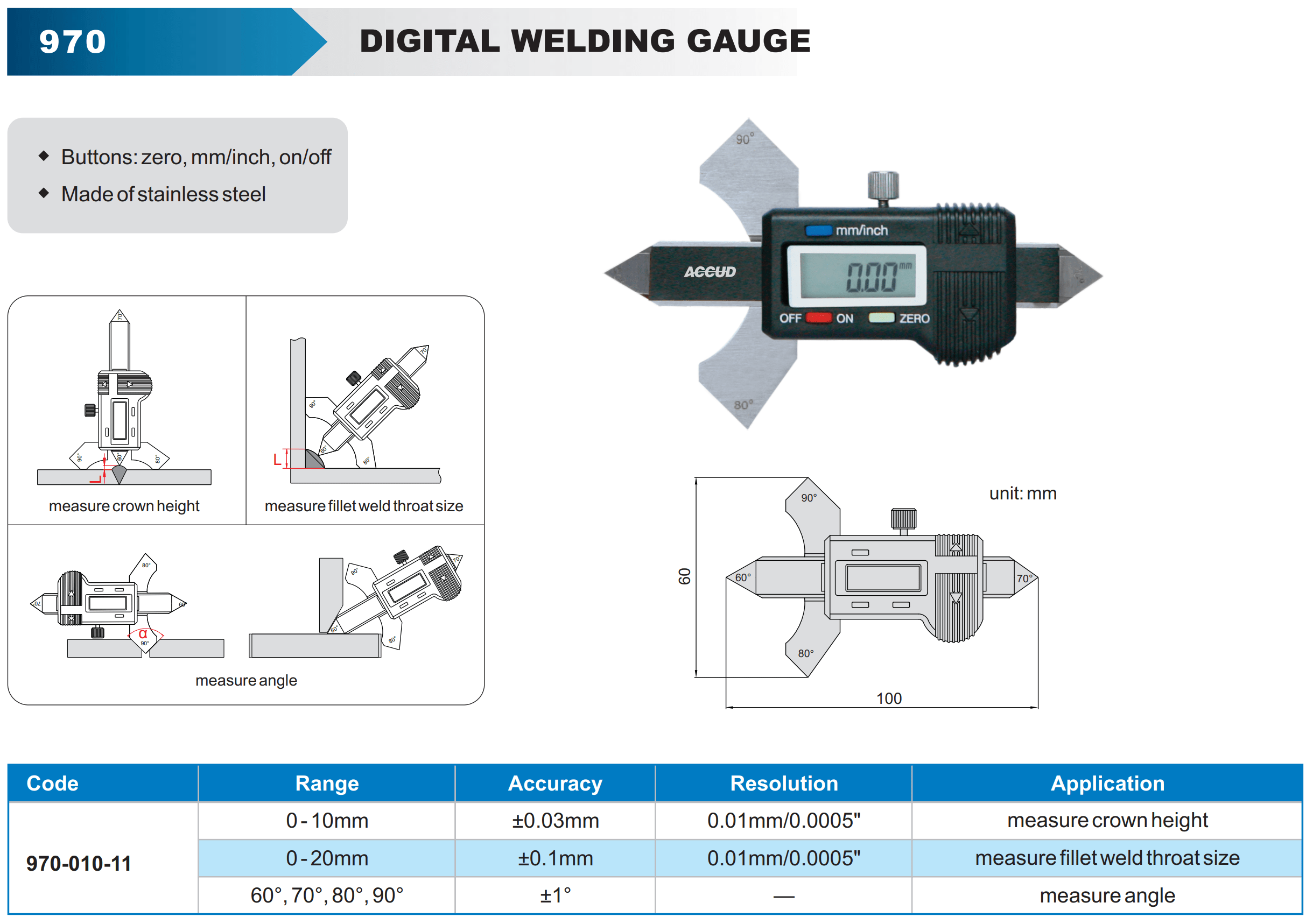

DIG. WELDING GAUGE 0-10MM/0-20MM/ 60,70,80,90DEG. S/STEEL

SERIES 970

A Welding Seam Gauge is a precision tool used to measure various dimensions of welds, such as the size, thickness, angle, and height of the weld seam. This tool helps ensure that welds meet specific quality standards and comply with design requirements in industries like construction, shipbuilding, automotive, and fabrication. It is an essential tool for welders and inspectors to evaluate the quality and integrity of a weld.

- Buttons: zero, mm/inch, on/off

- Measures crown height

- Measures fillet weld throat size

- Measures angle

- Made of the stainless steel

Applications

-

Quality Control in Welding:

- Weld Inspection: Used to check the size, angle, and other critical dimensions of a weld seam to ensure it meets required standards (e.g., AWS, DIN, ISO).

- Defect Detection: Helps identify welding defects such as underfilled or overfilled welds, improper throat size, or incorrect angles that could affect the weld's strength.

-

Fabrication and Construction:

- Pre-Weld Setup: Ensures the correct fit-up, angle, and alignment of parts before welding begins, minimizing errors during the process.

- Post-Weld Inspection: Used after welding to ensure that welds conform to design specifications and industry standards, reducing the risk of structural failures.

-

Shipbuilding, Automotive, and Aerospace:

- Precision Welding: In industries where precision and safety are critical, such as shipbuilding, automotive, and aerospace, a welding seam gauge ensures weld integrity and structural soundness.

-

Education and Training:

- Training Aid: Frequently used in welding education to teach apprentices and new welders how to inspect and measure welds accurately, promoting good welding practices.

A Welding Seam Gauge is an essential tool for welders, inspectors, and fabricators to ensure that welds meet required specifications and quality standards. It provides a quick and accurate way to measure critical weld dimensions such as size, throat thickness, and angles. Durable, portable, and multi-functional, it is widely used in industries where weld quality is paramount to safety and performance.

Key Features of a Welding Seam Gauge:

-

Measurement Functions:

- Weld Size (Leg Length): The gauge measures the size of the fillet weld’s legs, which are the two sides of the triangular fillet weld.

- Throat Thickness: Measures the weld throat, which is the shortest distance between the weld root and the face, ensuring the weld’s strength.

- Weld Height: Determines the height of the weld reinforcement on the surface of the workpiece to avoid excessive or insufficient material.

- Angle Measurement: Some gauges are equipped to measure the angle of the weld, ensuring it conforms to design requirements.

- Gap Measurement: Checks the gap between parts before welding, ensuring proper alignment and fit-up.

-

Construction Material:

- Stainless Steel: Made of stainless steel for durability, corrosion resistance, and longevity in harsh industrial environments.

- Engraved Markings: Clear, easy-to-read engraved / laser-etched markings on the gauge ensure precise measurements and are resistant to wear.

-

Multi-Functionality:

- Multiple Gauges in One Tool: Many welding seam gauges combine multiple measuring functions into one tool, making it convenient for welders and inspectors to perform several checks with a single instrument.

-

Portable Design:

- Compact and Lightweight: The tool is small and easy to carry in a pocket or tool pouch, making it highly portable for use in the field or on the shop floor.

Technical Specifications

Usage Tips:

- Proper Gauge Positioning: Ensure the gauge is properly placed against the weld seam or joint to get an accurate measurement.

- Clean the Weld Surface: Ensure that the weld surface is free from debris or spatter to get precise readings.

- Use Multiple Functions: For comprehensive inspection, measure all critical aspects of the weld seam, including size, angle, and throat thickness.

- Store Properly: Keep the gauge clean and store it in a protective case to avoid damage to the markings and measuring surfaces.